Hot Cold rolling Seamless Pipe Welded Machine

Project overview

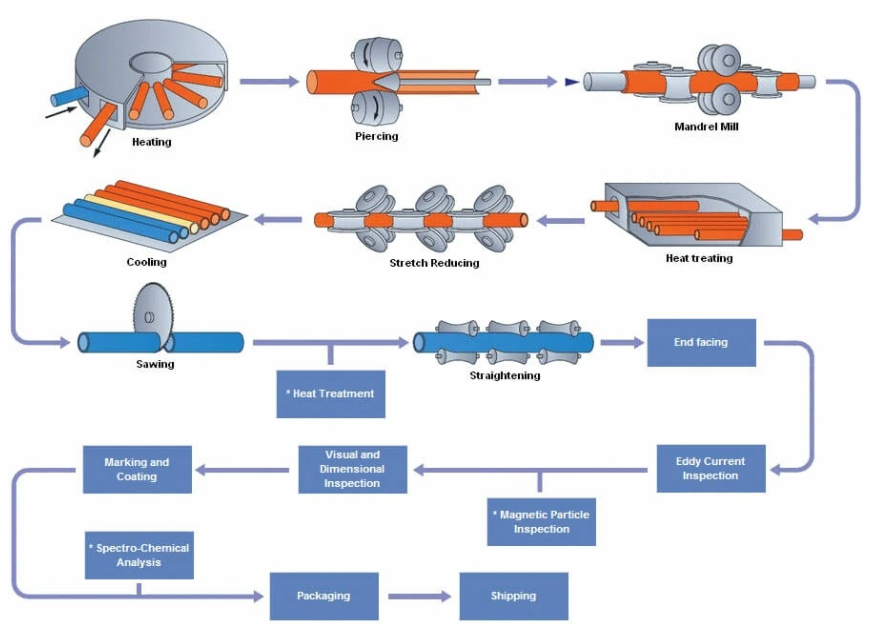

Seamless pipe mill is a type of equipment for producing seamless steel pipes, mainly composed of rolling machines, heating furnaces, cooling devices, cutting machines, etc. Its working principle is to heat the steel billet to an appropriate temperature and then use multiple rolling, stretching and other processes on the rolling machine to form seamless steel pipes. Seamless pipe units are widely used in fields such as oil, natural gas, chemical, aviation, and aerospace. With the continuous progress of technology, the production efficiency and product quality of seamless tube units have also been significantly improved.

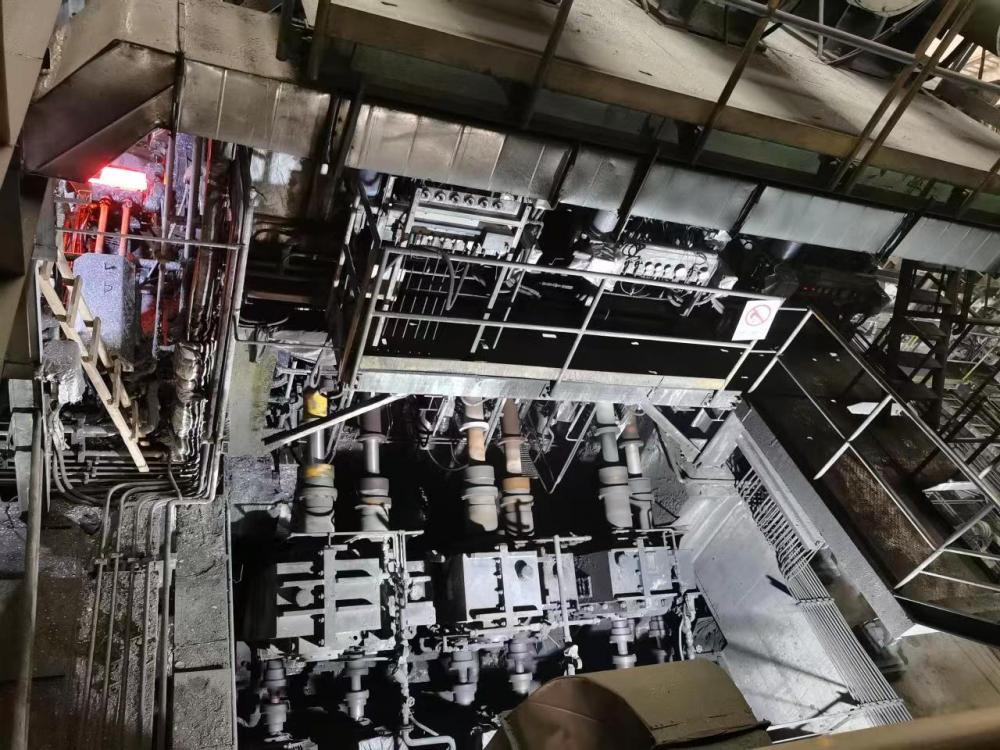

According to customer's requirements, the Ф90A-R hot rolling line is arranged. The unit adopts walking beam heating furnace, new type of cone type piercing mill, precision A-R pipe Rolling mill, SRM, chain type cooling bed, and ten rolls high precision straightening machine and other advanced equipment. The annual output of the unit is about 40,000 tons.

Parts of technical details

| No. | Item | Pipe size | Steel grade | Capacity | Standard |

| | | OD mm | WT mm | L m | | | |

| 1 | Oil pipe,linepipe | 33.4 | 3.38 | 12 | J,K,N,L,P | | API 5DP |

| 2 | Oil pipe,linepipe | 33.4 | 4.55 | 12 | J,K,N,L,P | | API 5DP |

| 3 | Oil pipe,linepipe | 33.4 | 6.35 | 12 | J,K,N,L,P | | API 5DP |

| 4 | Oil pipe,linepipe | 42.2 | 3.56 | 12 | J,K,N,L,P | | API 5DP |

| 5 | Oil pipe,linepipe | 42.2 | 4.85 | 12 | J,K,N,L,P | | API 5DP |

| 6 | Oil pipe,linepipe | 42.2 | 6.35 | 12 | J,K,N,L,P | | API 5DP |

| 7 | Oil pipe,linepipe | 48.3 | 3.68 | 12 | J,K,N,L,P | | API 5DP |

Main equipment of the unit

--Billet cutting(Band saw) --Walking beam heating furnace --New type cone type piercing mill --Precision A-R pipe rolling mill --18 stands SRM --Induction heating furnace --Chain type cooling bed --Ten rolls high precision straightening machine --Pre-finishing line (pipe cutting, magnetic flux leakage testing, checking, measuring length and weight, marking) Process Drawing